Maestro 🚀

Project Bullet Points

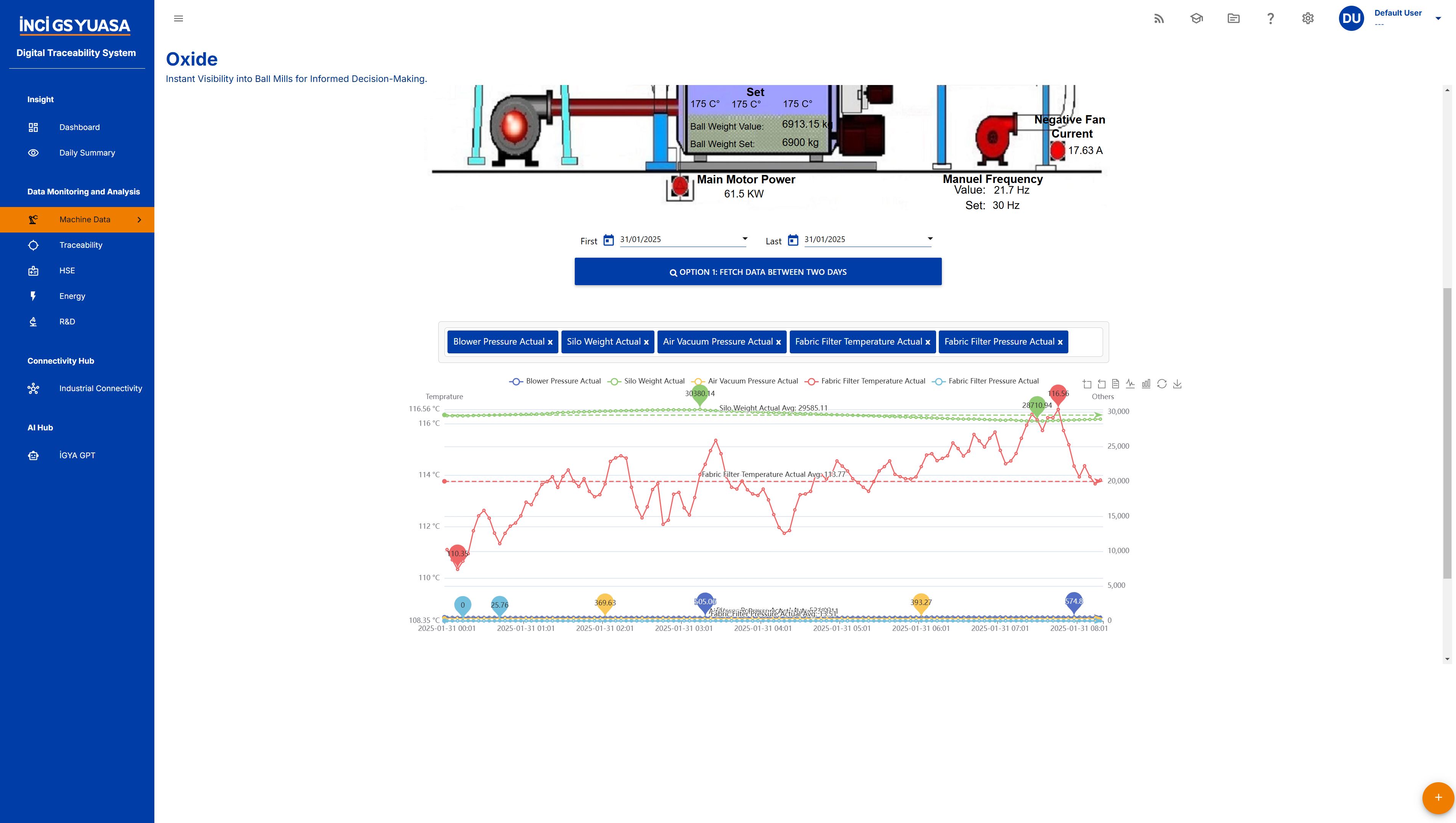

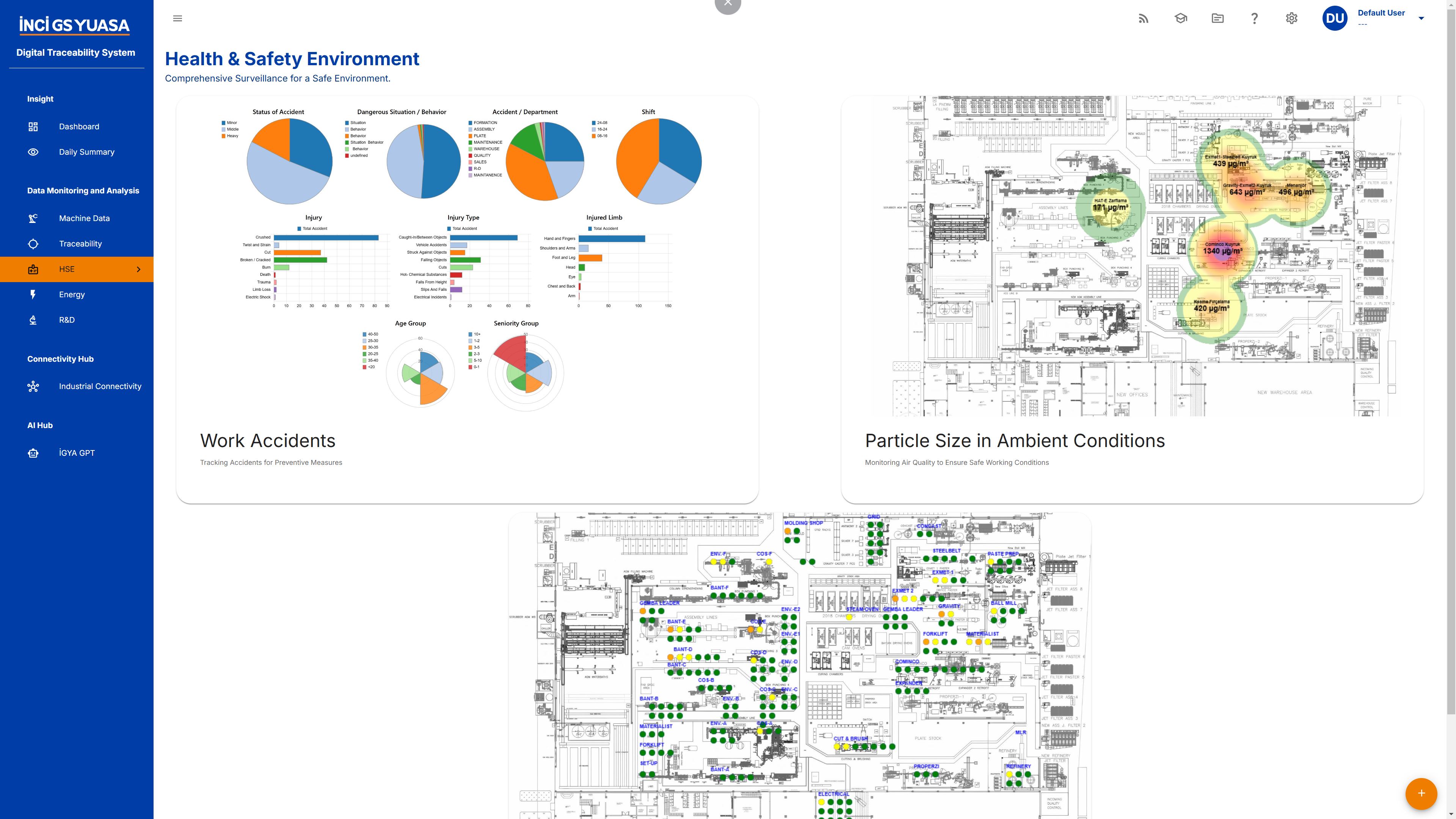

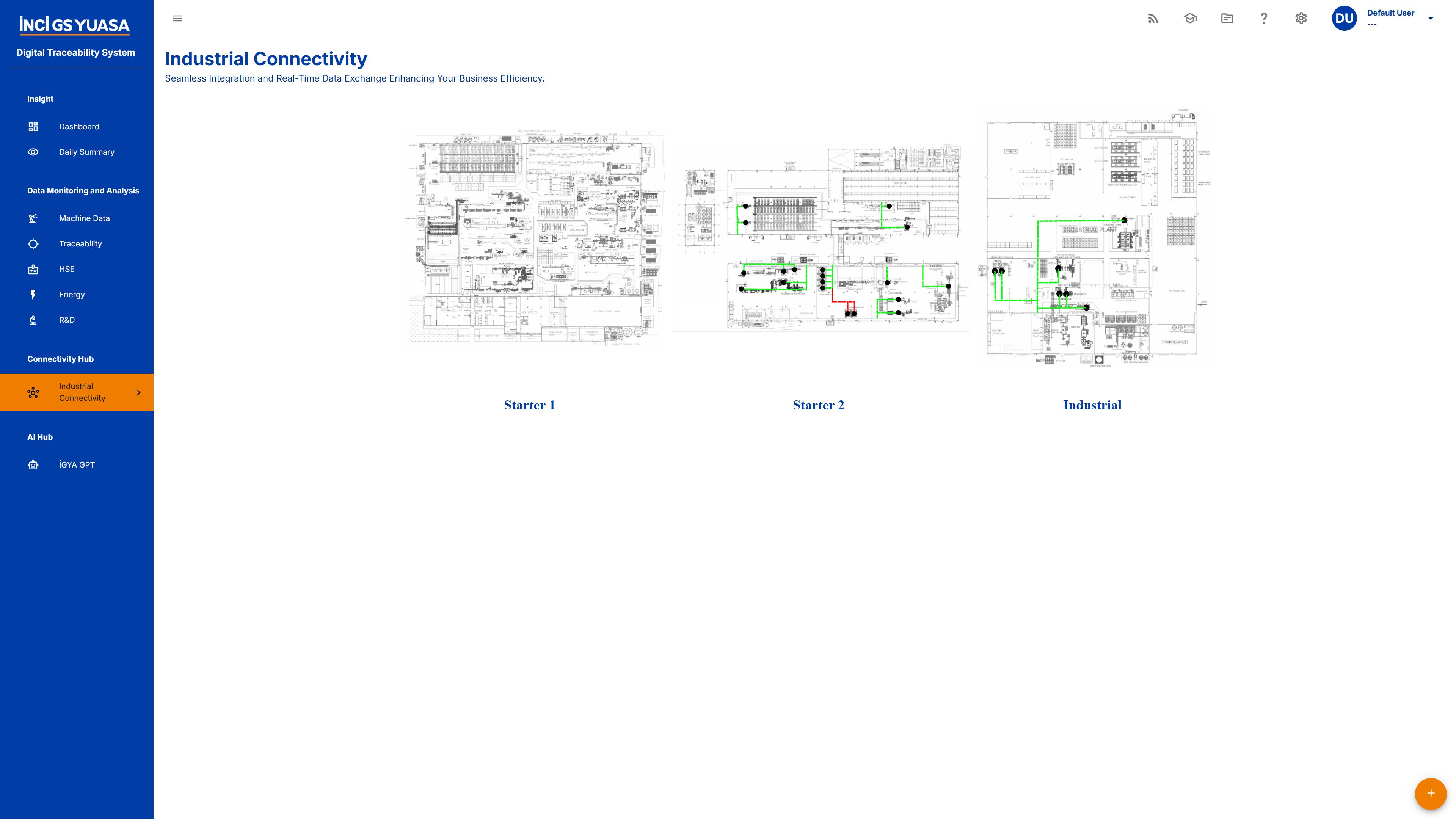

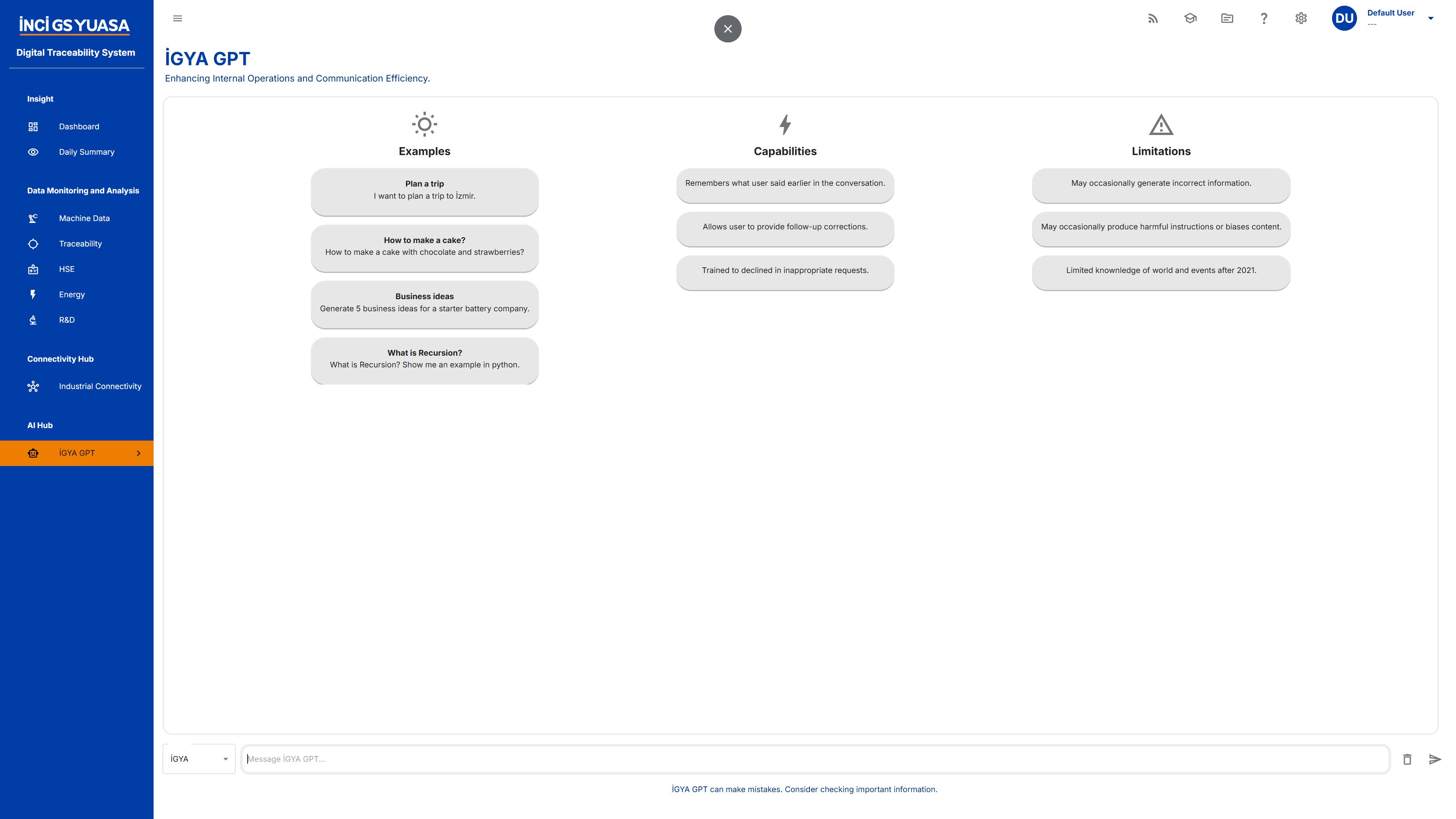

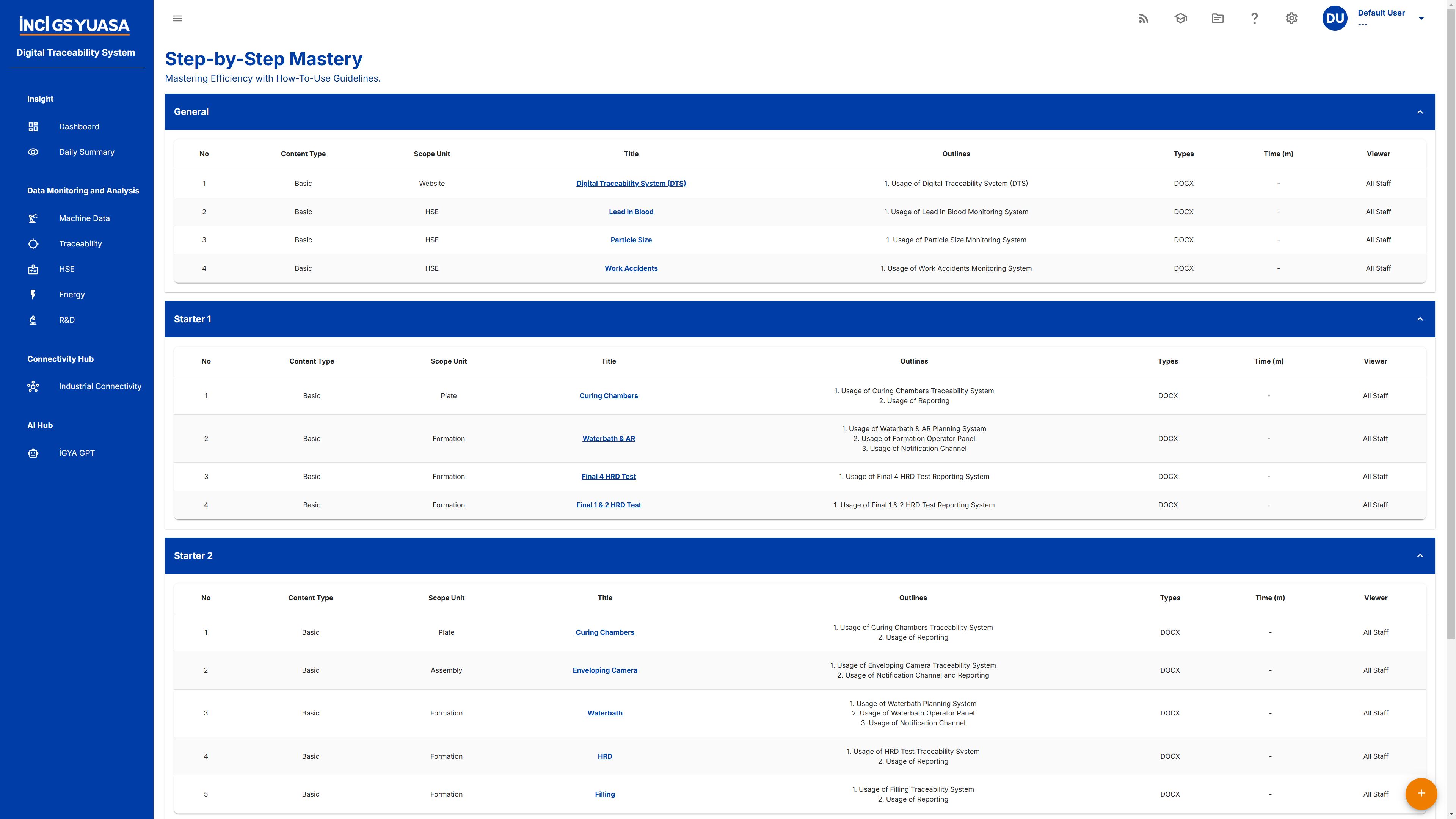

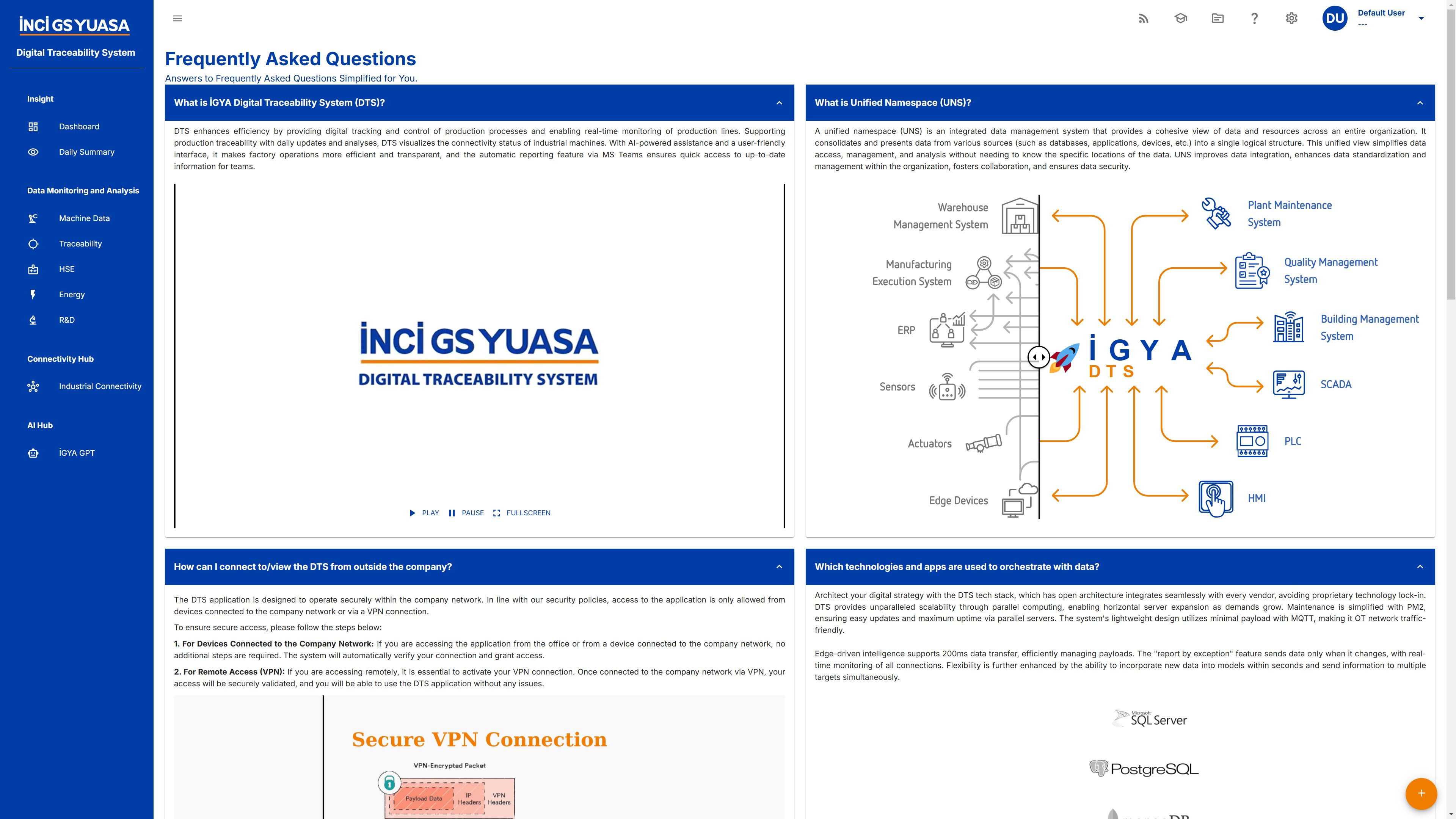

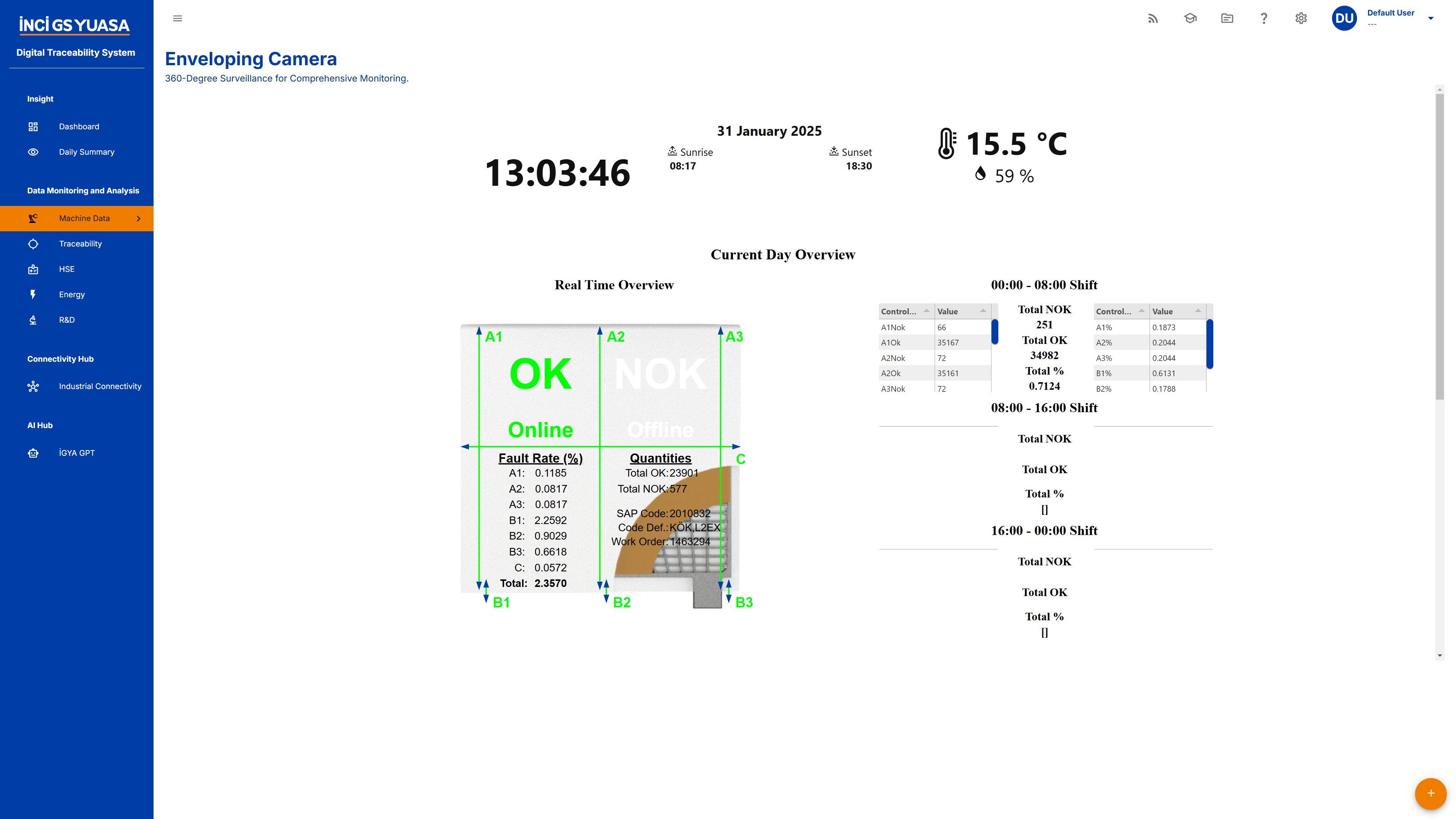

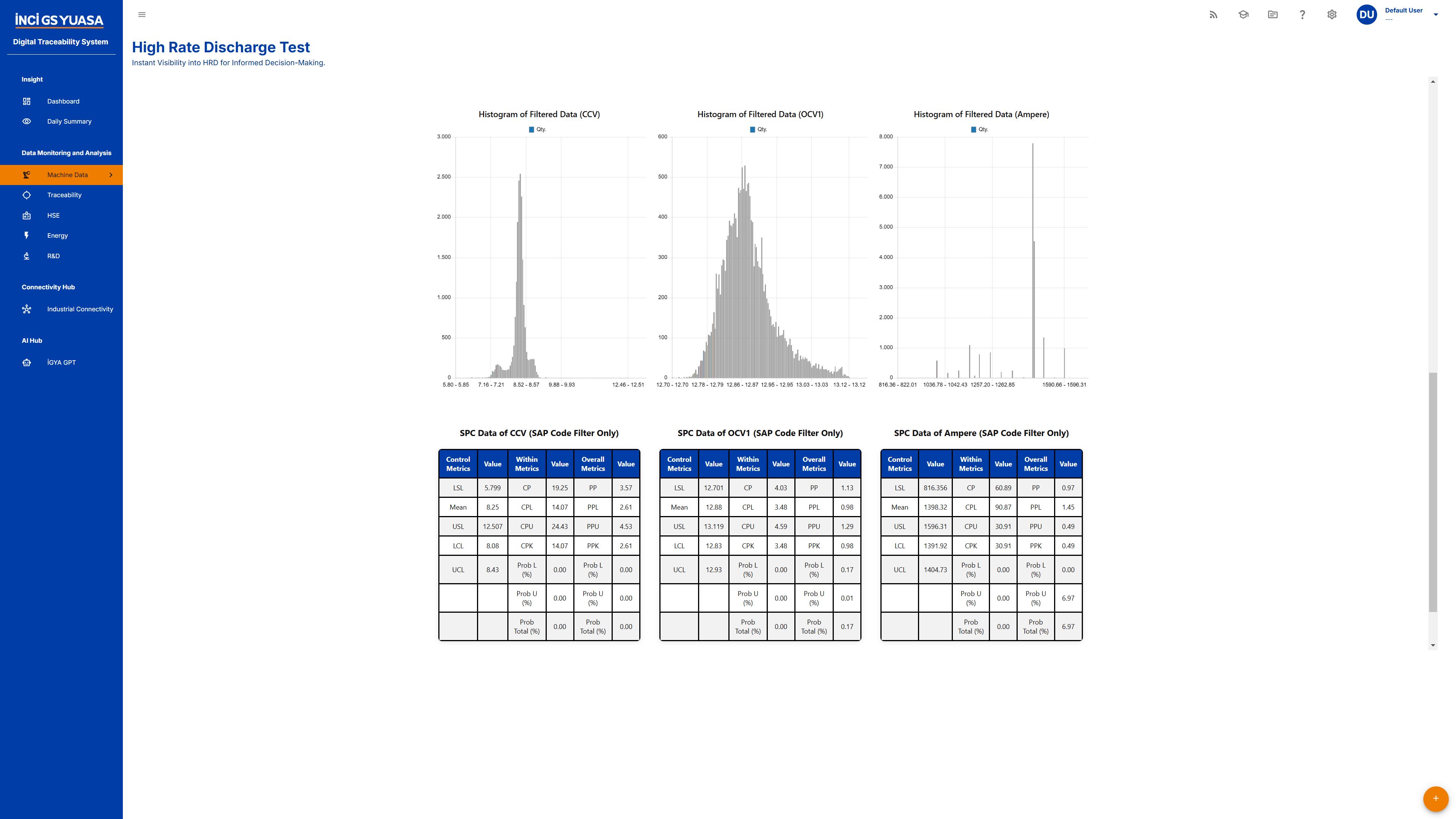

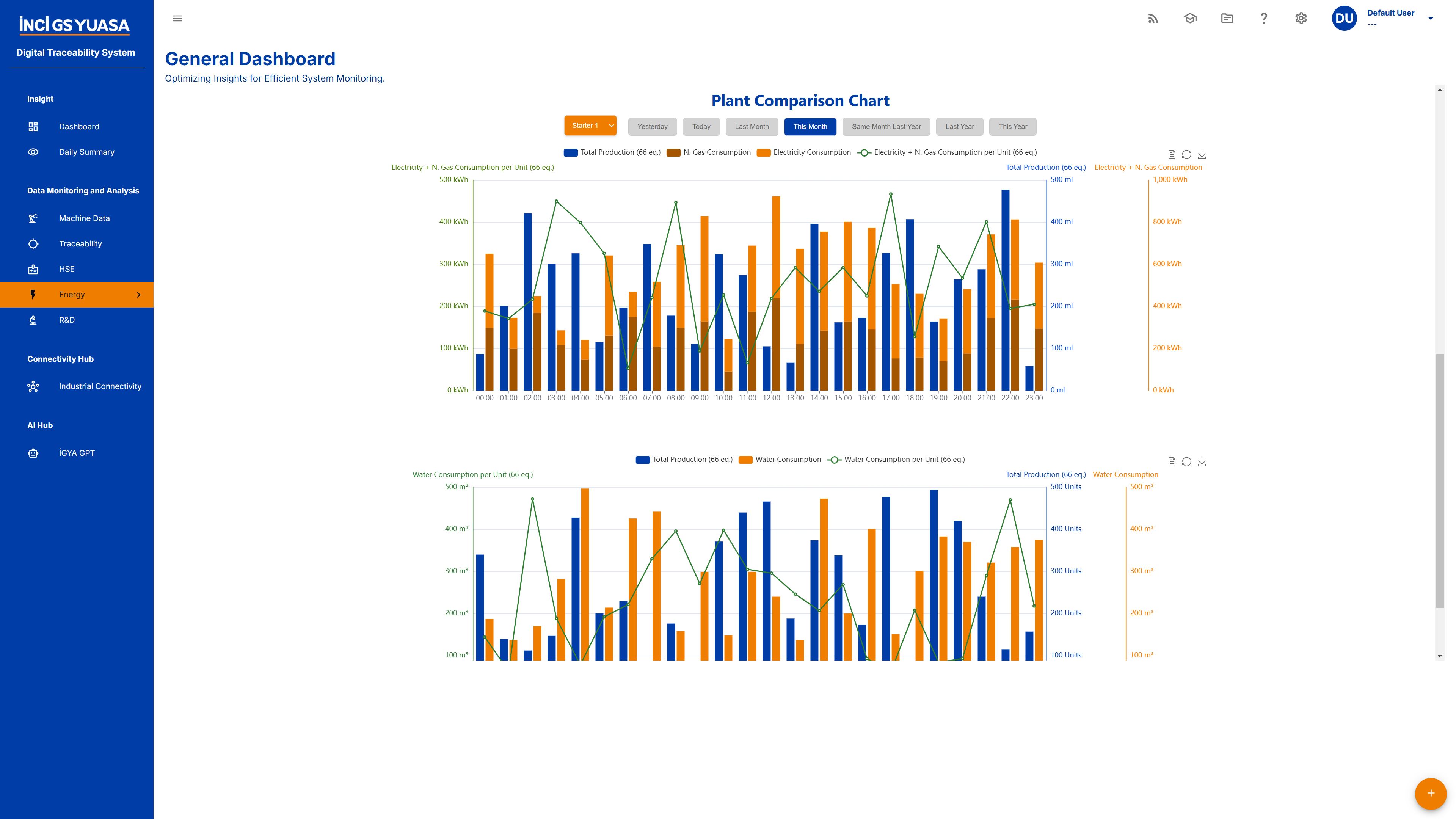

Led a team of 20 professionals to develop a web‑based digital traceability system, enhancing traceability by 40% through integration of SAP S/4 HANA, Energy Management , PLC systems, and IIoT devices.

Accelerated reporting time by 60%, generating annual savings of $156K by utilizing Kafka for data streaming, Node.js, and React.

Accomplished 19% increase in operational efficiency by reducing production cycle times, as measured by improved production throughput, through the implementation of a Unified Namespace (UNS) based on ISA95 standards.

Achieved 14% improvement in data reliability by enhancing real‑time data flow through the infrastructure optimization with OPC UA, MQTT, and Kafka, which also led to a 90% improvement in the response time to customer complaints.

Reduced production monitoring delays by 32%, as indicated by faster identification of production anomalies, by designing real‑time dashboards in Grafana and Node.js for lead‑acid battery manufacturing.

Led cost‑saving digital transformation initiatives, achieving a 57% reduction in operational expenses, as reflected by decreased overhead costs, by modernizing OT/ICS systems and integrating automation technologies.

Project Information

- Category Digital Transformation

- Client İnci GS Yuasa

- Project date Dec 2023